e-power your motion

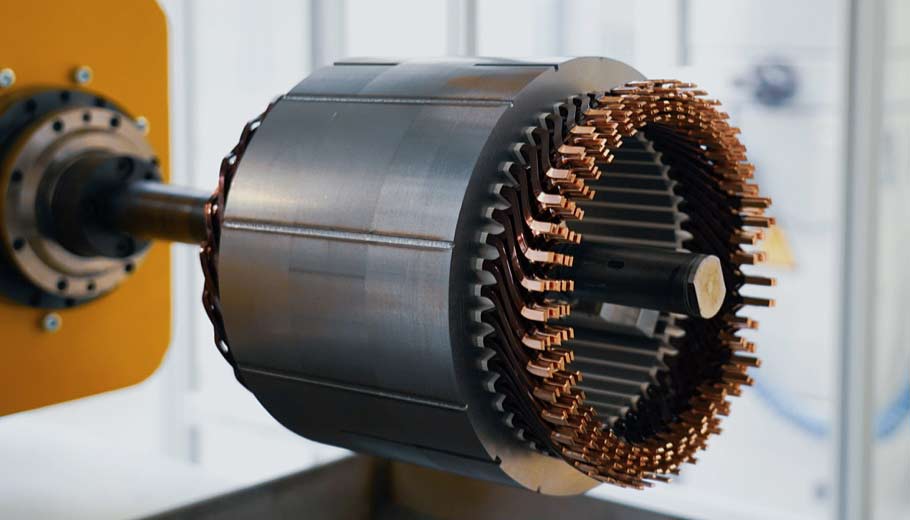

The eAx EM220

With our eAx EM220, we offer our customers a wide range of possible applications. Whether as a traction drive or as an electric power take-off we can cover various applications with our specialized variants of the EM220.

Typical applications for the eAx EM220

We provide a reliable and competitive electric drive system for you.

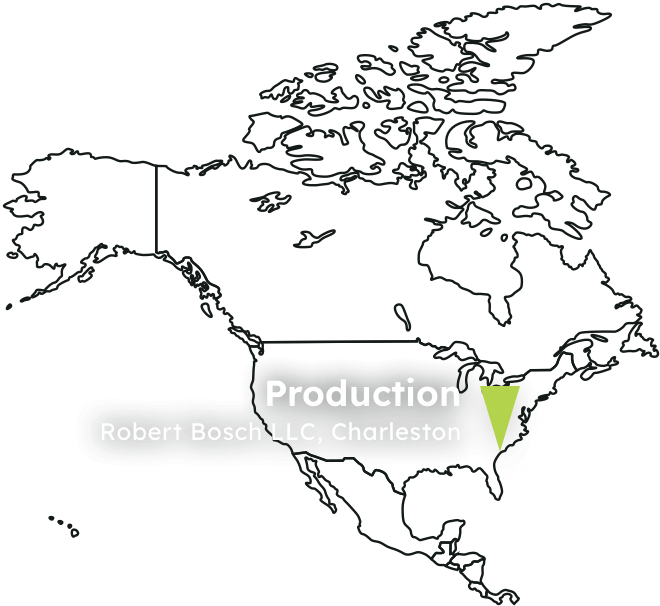

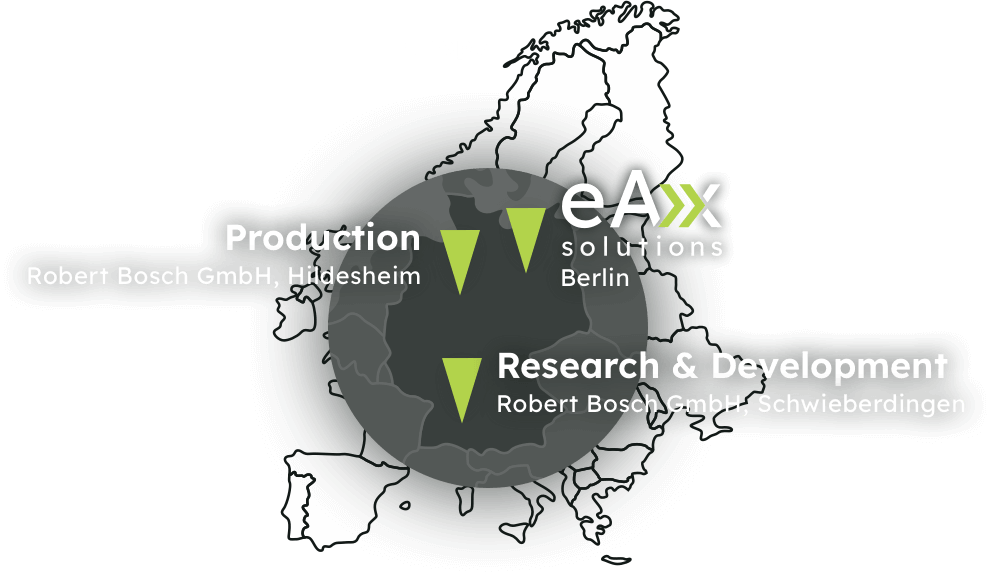

Our production

We produce the eAx EM220 at our manufacturing facility. Our production capabilities are highly adaptable to meet the unique requirements of our customers. Whether you need a small-volume sample production of just 10 units or a medium to high-volume serial production with a capacity of up to 15,000 units per year, we can accommodate your demands.

Our high-tech assembly line has been running since 2021, all set to create your electric machine right here in Berlin.

Integrated in a global expertise network

Get in touch with our Sales

We support our customers to electrify their vehicles and applications by focusing on the entire drive system. With our eAx EM220, we offer a robust and reliable electric machine. Working alongside our partners, we deliver a customized system that meets your individual requirements.